The Future of Fibre Optics: Why the Optical Fibre Diameter Analyser is Key to Advancements

The Future of Fibre Optics: Why the Optical Fibre Diameter Analyser is Key to Advancements

Blog Article

How an Optical Fibre Diameter Analyser Improves Quality Assurance in Fibre Production

The assimilation of an Optical Fibre Diameter Analyser into Fibre production procedures represents a substantial advancement in top quality control methodologies. By using real-time, precise measurements of Fibre diameters, this technology addresses the essential need for uniformity in production criteria.

Significance of Fibre Diameter Measurement

Exact dimension of Fibre Diameter is vital in the area of optical Fibre innovation, as it straight influences the efficiency and integrity of Fibre optic systems. The Diameter of an optical Fibre affects its light-carrying ability, attenuation, and overall transmission performance. Precision in gauging Fibre Diameter makes certain that the optical properties are maintained within specified resistances, which is essential for optimal signal honesty.

Variations in Fibre Diameter can lead to enhanced losses due to scattering and modal dispersion, impacting the high quality of data transmission. In high-speed communication systems, such disparities can result in substantial deterioration of signal high quality, causing information errors and reduced efficiency. Constant Fibre Diameter is necessary for compatibility with adapters and splicing innovations, which are important components of Fibre optic networks.

Quality assurance procedures in Fibre manufacturing greatly count on exact Diameter dimensions to guarantee conformity with sector criteria. By carrying out robust measurement techniques, producers can improve item reliability, reduce waste, and boost general system efficiency. Thus, the significance of Fibre Diameter measurement can not be overemphasized, as it offers as a keystone in the development of optical Fibre modern technology and its applications in modern communication networks.

How the Analyser Works

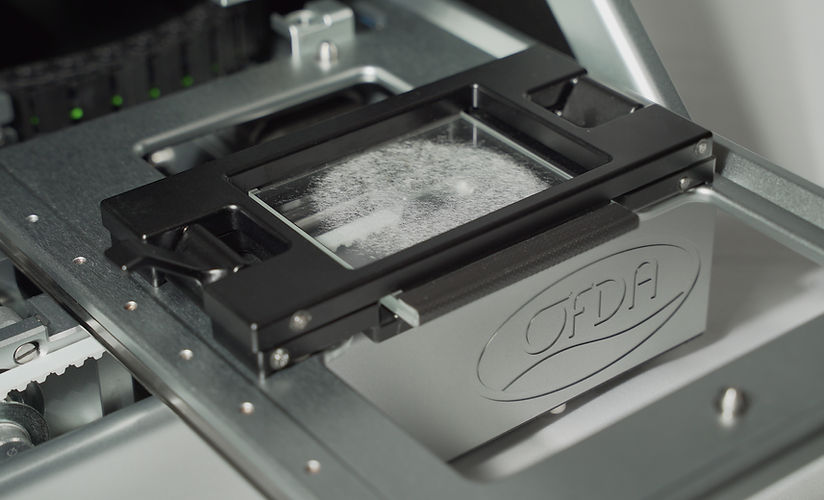

The effective measurement of Fibre Diameter relies upon sophisticated analytical methods that guarantee accuracy and integrity in optical Fibre manufacturing (optical fibre diameter analyser). The Optical Fibre Diameter Analyser employs a mix of laser technology and progressed photo handling formulas to precisely examine the Diameter of fibers as they are produced

Originally, a laser light beam is routed at the relocating Fibre, producing a cross-sectional darkness. The analyser catches this shadow using high-resolution cameras placed tactically along the assembly line. The captured photos are then refined in real-time to identify the Fibre's Diameter with outstanding accuracy.

The system makes use of innovative algorithms that account for different factors, consisting of variations in light strength and environmental problems, to boost measurement dependability. It can identify minute changes in Diameter, such as fluctuations that may occur during the production process.

In addition, the analyser is qualified of taking care of numerous fibers at the same time, raising throughput without endangering accuracy. By giving instant responses on the Diameter, the Optical Fibre Diameter Analyser plays an important role in preserving stringent quality assurance criteria, ensuring that the last product meets sector requirements and consumer requirements.

Advantages of Real-Time Surveillance

While conventional methods of monitoring Fibre Diameter commonly include time-consuming post-production checks, real-time surveillance dramatically boosts the efficiency and quality of optical Fibre production. optical fibre diameter analyser. This proactive strategy allows producers to determine variances in Fibre Diameter as they take place, rather than waiting up until manufacturing is total to examine top quality

By continuously measuring the Diameter throughout manufacturing, producers can guarantee that the fibres satisfy strict requirements, causing decreased check this site out irregularity and improved consistency. Real-time surveillance likewise allows instant corrective activities to be taken, minimizing waste and avoiding defective fibres from getting in the supply chain.

Moreover, this modern technology helps with improved information collection and analysis, supplying insights into manufacturing trends and possible locations for improvement. Such data-driven decision-making equips producers to maximize procedures and keep high standards of high quality control.

In addition, real-time monitoring promotes a society of continuous improvement within the manufacturing setting. Workers are more involved when they can see the influence of their job in real-time, bring about enhanced accountability and a dedication to excellence. Generally, the execution of real-time surveillance systems in optical Fibre manufacturing equates to exceptional item quality and increased consumer complete satisfaction.

Effect On Production Performance

Executing optical Fibre Diameter analysers significantly boosts manufacturing effectiveness by simplifying wikipedia reference the manufacturing process. These gadgets help with continuous surveillance of Fibre Diameter, permitting producers to detect deviations in real-time. By identifying variances promptly, assembly line can be changed rapidly, reducing downtime and lowering the possibility of generating faulty items.

Furthermore, the integration of these analysers into the production workflow makes it possible for much better source allotment. With accurate Diameter measurements, drivers can enhance product usage, guaranteeing that sources are not lost on flawed fibres. This precision likewise contributes to less junk and rework, inevitably lowering manufacturing costs.

The automation given by optical Fibre Diameter analysers lowers reliance on hand-operated assessments, which are frequently taxing and prone to human mistake. Consequently, employees can concentrate on even more critical jobs, improving overall productivity.

Additionally, the data created from these analysers can notify process renovations and promote much better decision-making. By analyzing patterns in Fibre Diameter variants, makers can execute aggressive procedures to enhance manufacturing strategies and preserve regular quality. In recap, optical Fibre Diameter analysers play a crucial role in improving production performance, causing higher high quality result and increased productivity.

Study and Success Stories

Throughout numerous fields, instance researches highlight the transformative impact of optical Fibre Diameter analysers on manufacturing procedures. One prominent instance is a leading telecoms business that encountered challenges with inconsistent Fibre diameters, bring about raised rejection rates. view website By incorporating an optical Fibre Diameter analyser, the business attained real-time monitoring of Fibre measurements, resulting in a 30% reduction in issues and significant cost savings.

Additionally, a study organization concentrating on advanced materials utilized optical Fibre Diameter analysers to improve their speculative procedures. The analyser's capability to supply comprehensive understandings right into Fibre consistency made it possible for the advancement of cutting-edge materials with better performance attributes.

These success tales highlight the important role of optical Fibre Diameter analysers in enhancing top quality control, improving production effectiveness, and driving development throughout varied markets.

Verdict

In final thought, the Optical Fibre Diameter Analyser plays a pivotal duty in improving high quality control within Fibre manufacturing. As shown through numerous instance studies, the analyser confirms vital for achieving exceptional item top quality in Fibre manufacturing.

The implementation of optical Fibre Diameter analysers allowed for rigid high quality control, making sure that the generated fibers met exacting sector criteria.In conclusion, the Optical Fibre Diameter Analyser plays a critical role in enhancing top quality control within Fibre manufacturing.

Report this page